ABOUT OGSO

So, here’s the lowdown: OGSO skis are our brainchild, cooked up entirely in-house and then brought to life in the Kaestle factory, basically the most high-tech ski factory on the planet.

Engineering: The OGSO Way

We don’t just slap together skis. We treat geometry, materials, flex, and mass distribution like a squad that works together. Everything’s connected, and the goal? A ski that behaves predictably no matter what kind of snow mood you’re dealing with.

Every model nails three big things: it stays stable on all kinds of terrain, it keeps edges predictable on firm snow, and it’s balanced so you can move efficiently both uphill and down.

Digital Design Vibes

Before we even cut a physical prototype, it’s all digital wizardry. We do 3D CAD modeling to dial in every curve and angle, run FEA simulations to see how everything flexes and responds, and layer up materials digitally so we know exactly how they’ll play together in the real world.

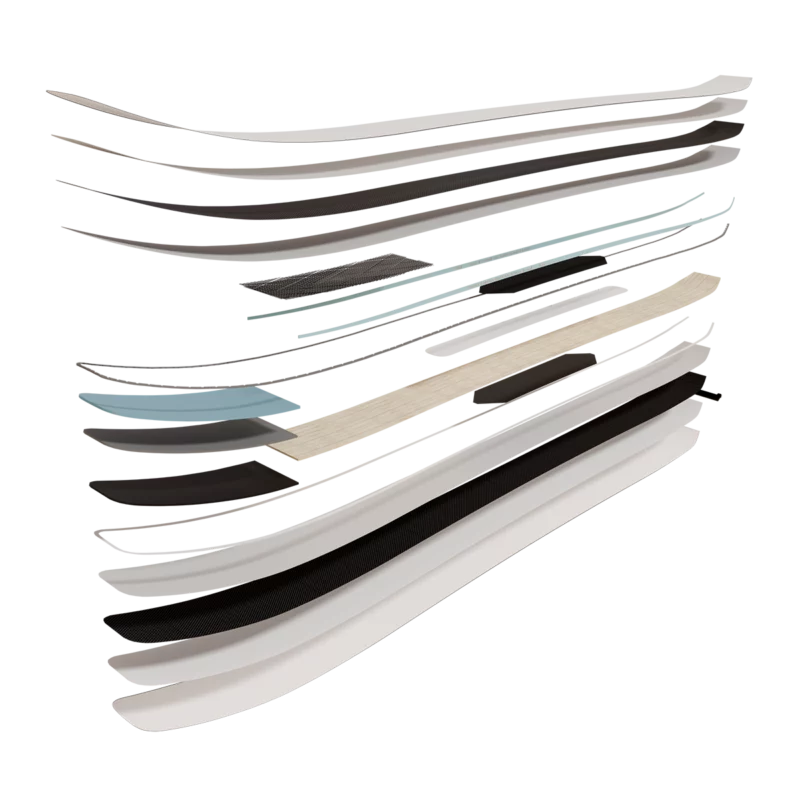

Materials & Build

We’re mixing up hybrid constructions for max versatility and durability. Think multi-density wood cores that we CNC profile for perfect flex zones, in-house engineered carbon–Kevlar fibers, and super tough sidewalls and bases that handle all kinds of snow temps. We’re not just shaving off grams for the sake of it, we put weight where it actually helps stability..

Prototyping & Testing

We run through hundreds of iterations tweaking everything from fiber orientation to rocker geometry, then we take these skis out into actual mountains. We’re talking powder, crust, steep entries, you name it. If the data doesn’t match real-world vibes, we don’t settle.

Built for the Real Mountain Heads

These skis aren’t about park tricks or resort laps. They’re for guides, mountaineers, expedition skiers, people who need their gear to back them up when the mountain throws surprises. We’re all about function over hype and precision over flashy marketing. If it doesn’t hold up in the wild, it doesn’t get to be an OGSO ski.